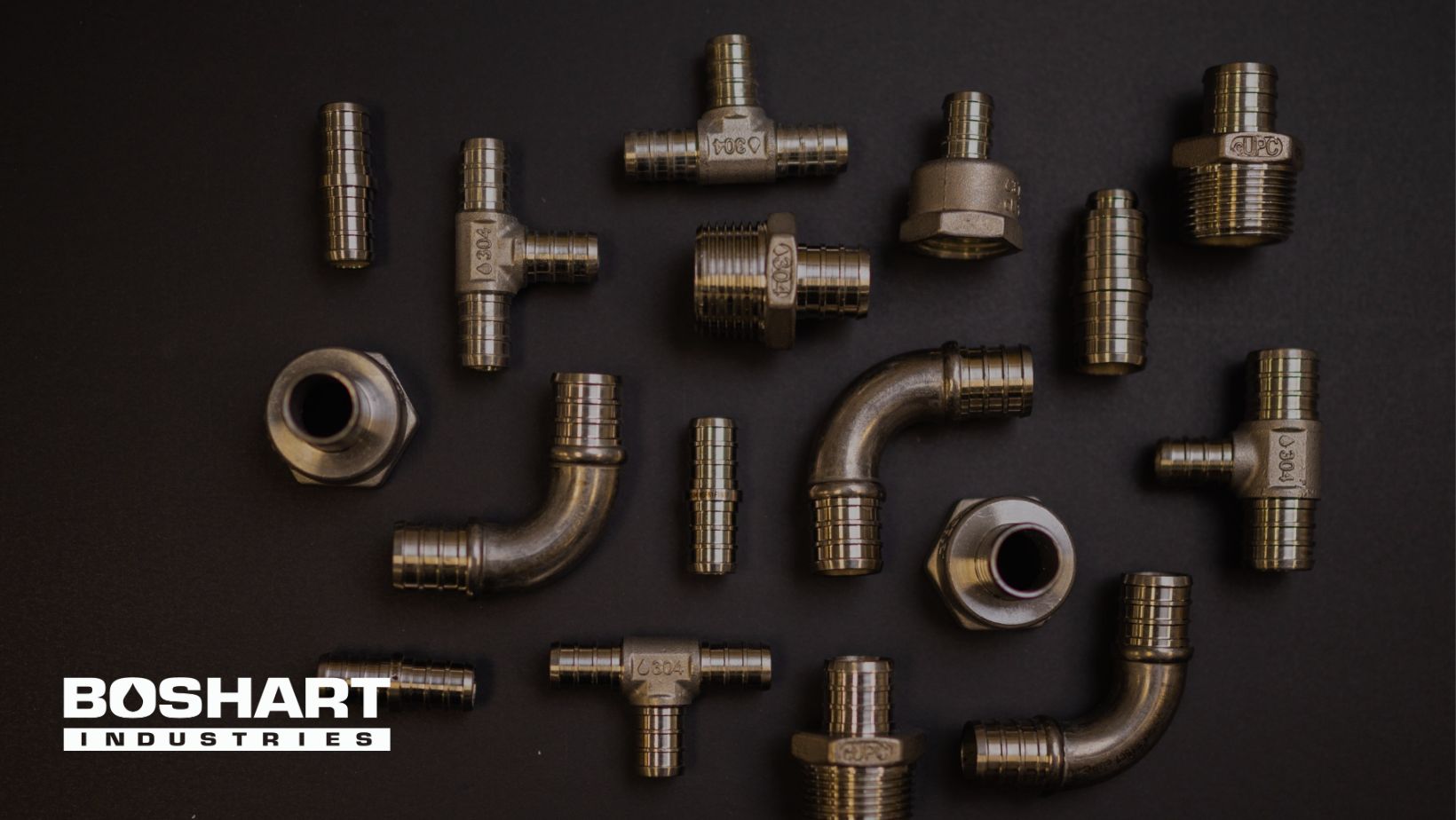

Stainless steel fittings display a lot of enticing characteristics but they are known to seize or pick-up during assembly or disassembly, frequently known as galling. Cold welding of the high points of oxide free metal left when the oxide film is dislodged by some surfaces rubbing together is thought to be the cause of galling. This is especially the case when threaded mating parts are the same grade and have the same surface hardness.

Stainless alloy is extremely hard and with the issue of galling, sealing stainless steel threaded connections can be a challenge compared to sealing brass or bronze alloy fittings.

We have gathered information that will reduce the issues and frustration that first time stainless fitting users come across. The below information explains the problems with sealing stainless fittings to stainless and will ensure a smooth transition making you comfortable with using stainless steel products.

Specialty tapes and thread seal compounds must be used to avoid any galling or seizing of the threads due to oxidation. Using both the specialty tape and the thread seal compound is a proven technique to a guarantee leak proof connection.

Stainless Steel Thread Seal Tape

Thread seal tape has been a staple in peoples tool boxes for years and years. To this day, it is still a reliable thread sealing solution for plumbing applications and for water systems.

Specialty stainless steel tape is a necessity for sealing NPT thread connections. It is gray in colour, a nickel pigment has been added for use with all stainless steel fittings. This particular tape is designed to prevent any galling, corrosion or seizing. Stainless steel specialty tape has a high density rating making it a perfect product for sealing stainless pipe threads.

DIRECTIONS:

- Start by using ½" wide tape dope.

- Put the end of the tape onto the first thread, not going past the end of the male pipe thread. You then need to hold the end in place using your thumb and wrap the tape in the opposite direction of the male pipe thread that turns into the fitting. Keep the tape under tension as you wrap to ensure the tape molds into the root of the thread.

- If you are using 3.5 or 4.0 mil tape, you should wrap three revolutions, anything thinner than 3.0 mil tape may require four to five full wraps around.

- Assemble joint normally.

Note: If the threads are damaged or poor quality, it may require more than three wraps of tape.

Pipe Joint Compound

Pipe joint compound is a non-seizing, all purpose thread sealing compound that provides a leak proof seal on all types of metal and plastic including stainless steel. The pipe joint compound is slow drying and non- hardening that is also lead free, non-toxic and can be used to seal threads on all different types of metal. It is ideal for stainless threads which are difficult to seal. You can also use it to seal plastic pipe fittings including ABS, CPVC, PVC, Nylon and Poly.

Pipe joint compound is a non-seizing, all purpose thread sealing compound that provides a leak proof seal on all types of metal and plastic including stainless steel. The pipe joint compound is slow drying and non- hardening that is also lead free, non-toxic and can be used to seal threads on all different types of metal. It is ideal for stainless threads which are difficult to seal. You can also use it to seal plastic pipe fittings including ABS, CPVC, PVC, Nylon and Poly.

DIRECTIONS:

- You should always wear gloves and eye protection when working with this compound.

- Clean any dirt, excess oil or grease from the threads.

- Make sure it is stirred well before using.

- Brush a good amount onto the male threads.

- Assemble joint normally.

NOTE: Always store the compound in a cool, well-ventilated area. Make sure the container is tightly closed.

In order to guarantee a leak proof connection, it has been proven and recommended that you first wrap the pipe threads with two or more rounds of gray stainless steel thread seal tape, finishing off by applying the pipe thread compound over the tape. This is something that is necessary on stainless steel pipes with a diameter of 4" and up. It has also been proven to be effective in preventing any leaks in all sizes of stainless steel threaded connections.

SHARE